DUPLEX STEEL – CHARACTERISTICS

Duplex steel (austenitic-ferritic) has balanced double-phase structure with more or less the same share of austenite and ferrite. Duplex steel has high content of chromium – from 19 to 32% and molybdenum – up to 5%. Strength properties of duplex steel and its resistance to acids and chlorides is higher comparing to austenitic steels. It can also be characterized with good resistance to pit, crevice and stress corrosion. Moreover, it can be characterized with increased plasticity, impact resistance and hardness.

We have the following products made of duplex steel in our offer:

- duplex double-T bars,

- duplex angles,

- duplex flat-bars,

- duplex C-beams,

- super duplex pipes,

- duplex pipes,

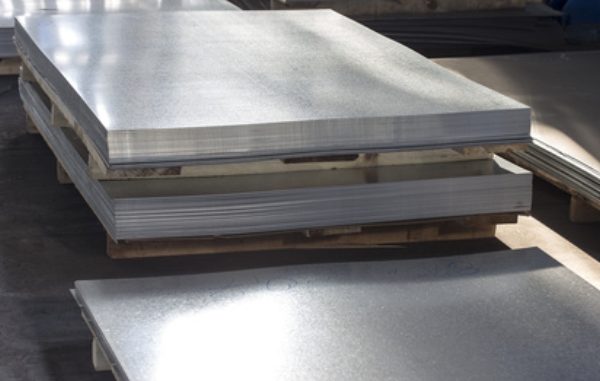

- duplex sheet.

The aforementioned assortment can also be offered in a few grades of duplex steel: 1.4362, 1.4460, 1.4462, 1.4501.

DUPLEX STEEL PROPERTIES

Duplex steel has high mechanical parameters. First and foremost it shows high resistance to general, intergranular, stress and pit corrosion. It also maintains very good resistance to corrosive cracking, abrasion and erosion. Duplex steel is magnetic, can be characterized by good weldability and mechanical machining as well as low thermal expansion. It does not harden as a result of heat treatment.

DUPLEX STEEL – MARKET SHARE

Duplex steel grades have about 2% market share in the global stainless steel production, however their application continuously grows.

WHEN TO APPLY DUPLEX STEEL?

Duplex steel is used when it is necessary to bind high mechanical strength and resistance to corrosion. It is mostly used in desalination systems, extractive industry and paper sector. There are also many bridge structures made completely of duplex steel.

DUPLEX STEEL – APPLICATION

Duplex steel is used in many sectors – in chemical, building and medical industry. It is used for production of pressure vessels, in food industry for construction of storage tanks, in cellulose processing. It is used to build large building structures (bridges, dams) and other architectonic elements that required durability under severe corrosive atmosphere. It is used to build petroleum and gas rigs.

SUPER DUPLEX STEEL

Super duplex steel is a high alloy steel grade. Comparing to duplex steel, it shows better resistance to pit, crevice and stress corrosion in contact with chlorides and acids. It is used in aggressive environment. Similarly to duplex steel, it has double-phase structure and is a combination of ferrite and austenite fractions. It can be characterized by better strength comparing to austenitic and ferritic steels. It is an alternative for the aforementioned grades due to lower cost of production, without reduction of quality and mechanical properties. The example of super duplex steel is the grade 1.4410 of chromium content 25%, molybdenum 4% and nickel 7%.

Super duplex steel is used in extractive, power and chemical industry. It is used for construction of rigs, pipelines, structures used in off-shore environment, for production of heat exchangers and other elements exposed to severe conditions.